En klädbalerningsmaskin (även känd som en textilbaltningsmaskin) är en särskilt tillverkad maskin baserad på förpackningskraven inom textilåtervinningsindustrin. Textilier kan paketeras för att spara lagringsutrymme och minska transportkostnaderna. Klädbalaren drivs av hydrauliskt tryck, trycket är stort, och manuell eller PLC automatisk kontroll kan väljas. Klädbalaren kan användas tillsammans med en materialtransportör. Denna textila baleringsmaskin är idealisk för textilproducenter, återvinning av avlagt kläder, avfalls- och klädeshandlare/exportörer och mer. Den passar små företag eller stora företag med textilåtervinningsproduktionslinjeer.

Ufungaji wa nguo ni nini?

Uunganishaji wa nguo ni kukandamiza nguo taka, nyuzi, vitambaa na nyenzo nyingine zisizo huru kwa wingi kuwa mistatili iliyoshikana, miraba na maumbo mengine. Nguo za taka za baled zinaweza kuokoa nafasi ya kuhifadhi, kupunguza gharama za usafirishaji, na kuwezesha kuchakata tena. Mashine ya kuwekea nguo ni kifaa muhimu cha kuboresha ufanisi wa kazi, kupunguza nguvu ya kazi, kuokoa nguvu kazi na kupunguza gharama za usafirishaji. Saizi ya sanduku la kulisha na sura na saizi ya marobota ya mwisho yanaweza kubinafsishwa kulingana na mahitaji maalum ya wateja.

Je, ni matumizi gani ya mashine ya baler ya nguo?

Maombi: nguo za taka, taulo, mito, blanketi, blanketi, viatu, vitambaa, nyuzi za nguo, chachi ya pamba, katani, pamba, uzi, ngozi, na taka zingine za nguo.

Kwa kuongezea, mashine ya kuweka nguo inafaa kwa kukandamiza plastiki taka, karatasi taka, katoni za taka, kadibodi ya taka, metali za taka, nk.

Utendaji wa baler ya nguo

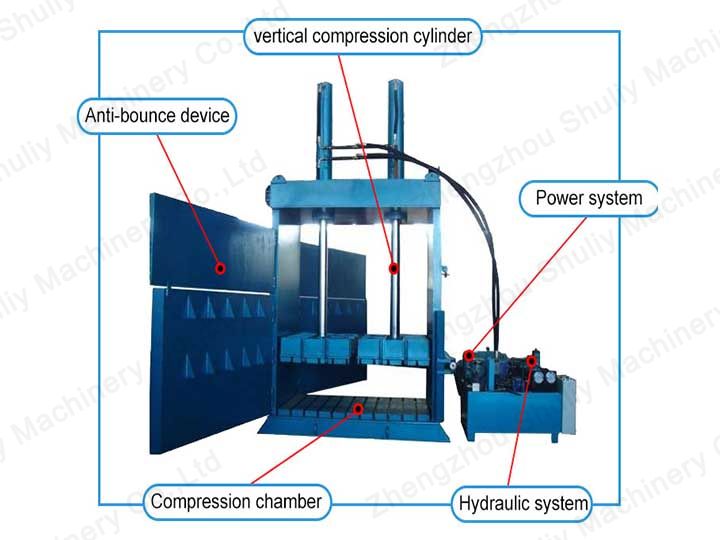

Silinda ya baler ya wima inachukua vifaa vya juu vya kimataifa, ambavyo vina utendaji mzuri wa kuziba, hakuna kuvuja kwa mafuta, na hakuna misaada ya shinikizo, ambayo inafanya bidhaa kudumu zaidi. Mashine ya baler ya nguo ina valve ya kurekebisha mwongozo, ambayo ni imara na ya kuaminika katika uendeshaji na rahisi kufanya kazi, na hatua inaweza kudhibitiwa.

Injini ina utendakazi mzuri wa kutawanya joto, pato la nguvu kali, na pato thabiti. Sura ya mashine ya nje imetengenezwa kwa sahani ya chuma iliyotiwa nene, ambayo si rahisi kuharibika chini ya shinikizo la juu, na ukandamizaji ni ngumu zaidi.

Kila mashine ya kusaga nguo hutumia mchakato wa kulehemu ili bidhaa iwe na upinzani mzuri wa ufa na si rahisi kuharibika. Nguvu ya baler ya hydraulic inaweza kuundwa kwa wakati mmoja bila rework. Mashine ya baler ya nguo ina ufanisi wa juu, ambayo ni mara kadhaa zaidi kuliko ile ya baler ya jadi.

Jinsi ya kuendesha mashine ya kusawazisha majimaji?

Mashine ya kusawazisha nguo otomatiki ni rahisi kufanya kazi. Chumba cha mgandamizo kilichoinuliwa hutengeneza nyuzi kwa urahisi, kuweka safu, na kutoa marobota kwa urahisi. Opereta anahitaji tu kubofya kitufe na chumba cha mgandamizo hujiinua kiotomatiki kabla ya kuunganisha na kuunganisha. Mchakato wote unaweza kuendeshwa na mtu mmoja tu, ambayo huokoa sana gharama za kazi.

Je, mashine ya kusawazisha nguo inagharimu kiasi gani?

Kama mtengenezaji wa viweka wima, tunatoa aina mbalimbali za vielelezo, ikiwa ni pamoja na aina za silinda moja na mbili, na aina za wima na mlalo. Shinikizo la majimaji ya mashine ya kuweka nguo za wima inaweza kufikia tani 30-120. Wauzaji wa nguo kwa ujumla wanaweza kutoa marobota kuanzia 30kg hadi 600kg. Saizi maalum ya bale inaweza kuamuliwa kulingana na mfano, ili kukidhi mahitaji ya wateja. Ikiwa una mahitaji maalum, tunaweza kubinafsisha usindikaji kulingana na mahitaji yako halisi. Jisikie huru kuwasiliana nasi wakati wowote.