La Machine de recyclage des couches pour bébés est une ligne de production complète conçue pour recycler efficacement les couches pour bébés usagées en coupant, détachant, tamisant et éliminant la poussière. Elle sépare efficacement la pulpe de flocons, le SAP, le non-tissé et le film PE pour une réutilisation des matériaux.

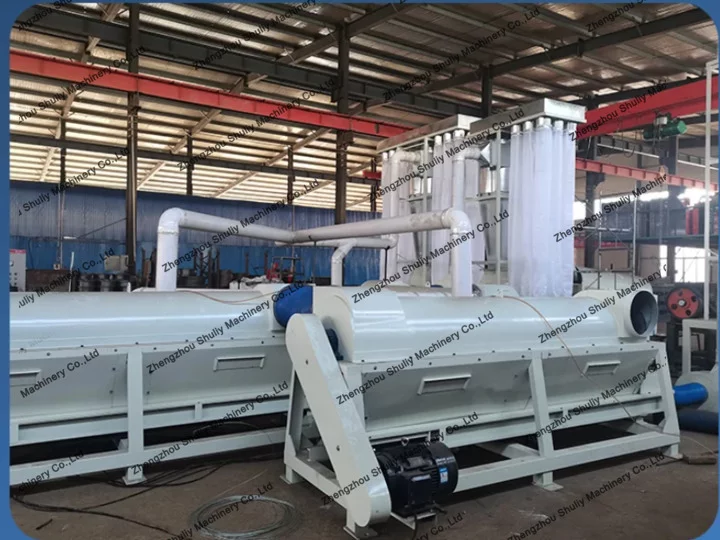

La ligne comprend une machine de coupe de fibres, une machine de détachage, une machine de tamisage du SAP, un collecteur de poussière à cyclone simple et un collecteur à cyclone double. Ces unités fonctionnent en harmonie pour assurer une séparation propre avec une perte minimale.

Avec une capacité de traitement de 300–400 kg/h, le système présente une structure compacte et des performances stables, ce qui le rend idéal pour les petites à moyennes usines de recyclage. La machine de recyclage des couches pour bébés offre un haut niveau d'automatisation, une maintenance facile, et supporte des configurations et dispositions personnalisées selon les besoins du client.

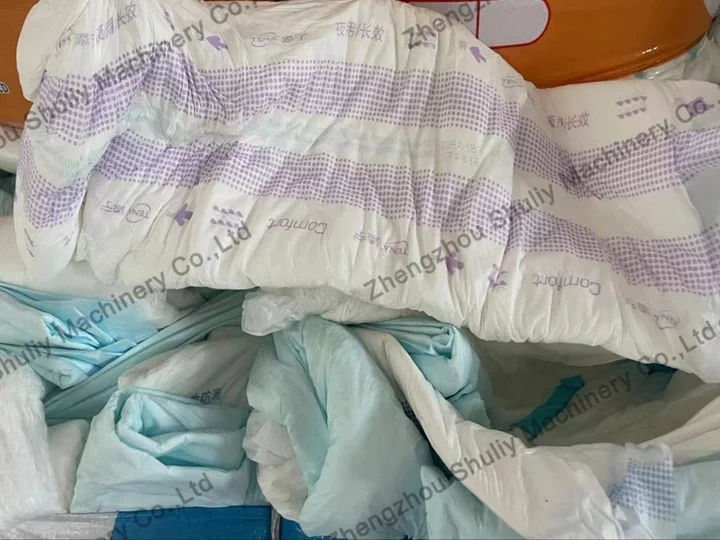

Quels matériaux conviennent à la machine de recyclage des couches pour bébés ?

- Couches / serviettes hygiéniques presque expirées – La machine peut traiter efficacement les produits approchant de la date d'expiration, en séparant les matériaux utilisables tels que la pulpe de flocons, le SAP, le non-tissé et le film PE pour une réutilisation secondaire.

- Produits défectueux ou non conformes de la ligne de production – Tout couche ou serviette hygiénique qui ne passe pas le contrôle de qualité peut être recyclée directement, réduisant ainsi le gaspillage de matériaux et les coûts de production.

- Déchets de coupe et rebuts de bordure générés lors de la fabrication – La machine peut traiter les matériaux résiduels de production, aidant les fabricants à récupérer des matières premières précieuses et à améliorer l'utilisation globale des matériaux.

Comment fonctionne la machine de recyclage des serviettes hygiéniques ?

- Alimentation en matériaux: Les couches usagées, les serviettes hygiéniques ou les produits défectueux sont versés dans la trémie du broyeur.

- Découpage et séparation: À l'intérieur de la chambre de broyage, la machine sépare rapidement la couche de papier extérieure des matériaux de remplissage internes, y compris les granules de SAP et les fibres de coton absorbant.

- Décharge séquentielle: Dispositifs de séparation spécialisés déchargent les matériaux en séquence, assurant une séparation propre et efficace.

- Réutilisation des matériaux: Le papier séparé peut être recyclé pour la fabrication de papier, tandis que le SAP et la pulpe de flocons peuvent être réutilisés dans diverses applications.

Avantages de la machine de recyclage des couches pour bébés

- Opération stable: Fonctionne en douceur avec peu de vibrations, garantissant une utilisation fiable à long terme.

- Haute productivité: Capable de traiter efficacement de grandes quantités de couches.

- Bruit faible: Fonctionne silencieusement, créant un meilleur environnement de travail.

- Séparation efficace: Sépare efficacement les couches de papier des fibres courtes absorbantes et des granules de SAP.

- Économie d'énergie: Consomme moins d'énergie comparé à des machines similaires, réduisant les coûts opérationnels.

Applications des matériaux de couches recyclées

- SAP recyclé: Utilisé dans les tapis pour animaux, substrats de semis, produits absorbants et matériaux retenant l'humidité, exploitant pleinement ses propriétés d'absorption et de rétention d'eau.

- Pulpe de flocons recyclée: Appliqué à la modification du plastique, aux matériaux isolants acoustiques, et à la production de papier ménager, offrant un large potentiel de réutilisation.

- Autres composants recyclés: Peut être utilisé comme combustible pour le chauffage ou la production d'électricité, réalisant une utilisation énergétique de matériaux de faible valeur.

Paramètres de la ligne de recyclage des couches pour bébés

Machine de coupe de fibres

| Paramètre | spécification |

|---|---|

| Nom de la machine | Machine de découpe de fibres |

| Puissance du moteur | 5,5 kW 1,5 kW |

| Dimensions (L×l×H) | 3200 × 1000 × 1100 mm |

| Capacité conçue | 300–400 kg/h |

| Vitesse de coupe | Vitesse de coupe : 432 coupures/min |

| Taille de coupe | 2,5–8 cm |

| Lames rotatives | 4 lames ultra-durcies |

| Lames fixes | 2 lames ultra-durcies |

| Convoyeur d'entrée | 1400 × 330 mm |

| Convoyeur de sortie | 1400 × 330 mm |

| Épaisseur de coupe | 30–50 mm |

| Contrôle électrique | Boîte de contrôle de protection thermique contre la surcharge |

Machine de défluffage de fibres

| Modèle | Machine de dispersion 1 | Machine de dispersion 2 | Machine de dispersion 3 |

|---|---|---|---|

| Puissance du moteur | 18,5 kW, 380V, 60Hz | 15 kW, 380V, 60Hz | 15 kW, 380V, 60Hz |

| Longueur de la machine | 2500 mm | 2500 mm | 2500 mm |

| Diamètre de la machine | Φ402 mm | Φ402 mm | Φ402 mm |

| Hauteur de la plaque de lancement | 100 mm | 100 mm | 100 mm |

| Nombre de plaques de lancement | 6 | 6 | 6 |

| Décharge inférieure | 3000 × 520 mm, 1,5 kW | 3000 × 520 mm, 1,5 kW | 3000 × 520 mm, 1,5 kW |

| Taille de l'écran | 10 mm | 8 mm | 6 mm |

| Soufflante | 4,0 kW | 3,0 kW | 3,0 kW |

Machine de tamisage du SAP

| Paramètre | spécification |

|---|---|

| Modèle | Machine de tamisage du SAP |

| Puissance du moteur | 11 kW 1,5 kW, 380V, 60Hz |

| Longueur de la machine | 3000 mm |

| Largeur de la machine | 1500 mm |

| Taille de l'écran | 0,4–0,8 mm |

Collecteur de poussière à cyclone

| Paramètre | Collecteur de poussière à cyclone simple (2 unités) | Collecteur de poussière à cyclone double |

|---|---|---|

| Puissance du moteur | 3,0 2,2 kW, 380V, 60Hz | 3,0 kW, 380V, 60Hz |

| Nombre de ports de décompression | Φ200, 9 chacun | Φ200, 18 |

| Diamètre du collecteur de poussière | Φ800 mm | Φ900 mm |

| Soufflante | 3,0 kW | 3,0 kW × 2 |

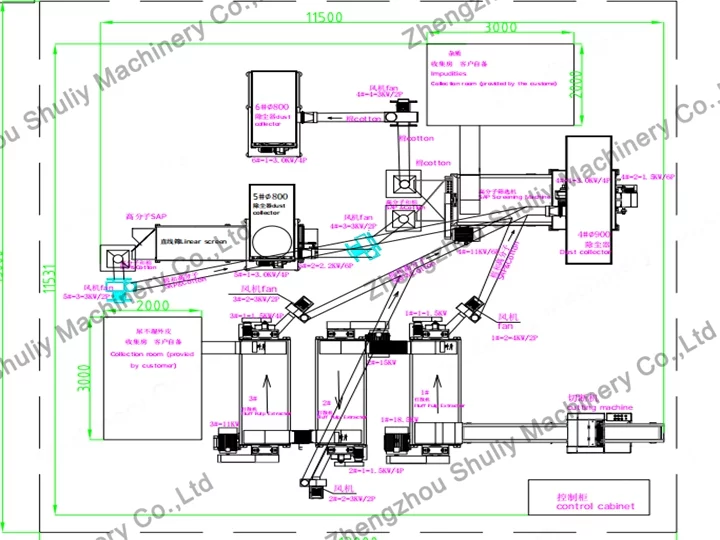

Disposition de la ligne de recyclage des couches pour bébés

Conclusion

La Machine de recyclage des couches est une solution très efficace, fiable et facile à utiliser pour recycler les couches usagées ou défectueuses, les serviettes hygiéniques et autres produits absorbants.

Ce système améliore non seulement l'utilisation des matériaux et réduit les coûts de production, mais soutient également des pratiques de recyclage durables.

En plus de la ligne de recyclage des couches, notre entreprise propose une large gamme d' autres équipements de recyclage pour diverses applications industrielles. Les clients sont invités à demander un devis et à explorer notre gamme complète de produits.