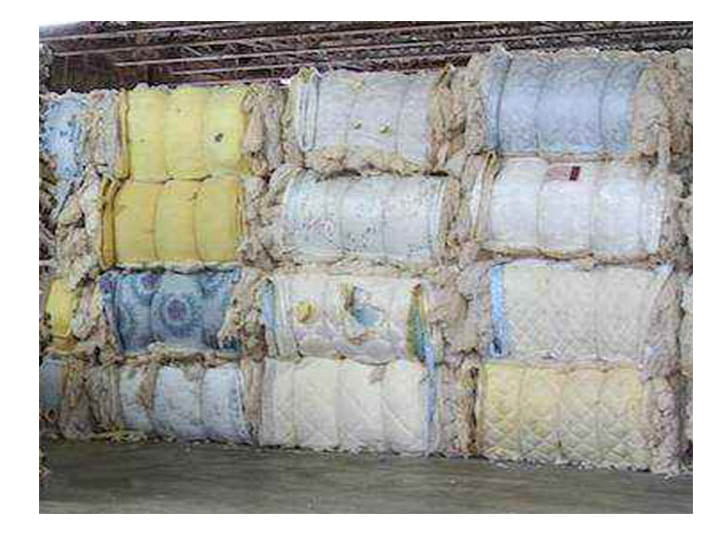

Baler hidrolik vertikal terutama digunakan untuk pengepresan dan pemulihan tekstil terkompresi, kapas, kain, serat, karton, film limbah, kertas limbah, plastik busa, kaleng minuman, skrap industri, dan bahan limbah lainnya. Untuk daur ulang serat, mesin baler serat sering diterapkan untuk membalut berbagai serat agar mudah disimpan dan diangkut dalam jalur daur ulang serat limbah. Mesin baler tekstil mengurangi ruang penyimpanan limbah, menghemat hingga 80% ruang penumpukan, mengurangi biaya transportasi, dan kondusif untuk perlindungan lingkungan dan pemulihan limbah.

Penggunaan mesin baling hidrolik vertikal

Rangkaian mesin baling hidrolik ini dapat digunakan untuk mengemas semua jenis produk limbah untuk didaur ulang. Dalam industri tekstil, mesin baling tekstil dapat mengolah berbagai jenis limbah kain, kapas, benang, wol, pakaian, sabut kelapa, serat rami, kulit, serat kimia, dll. Di industri daur ulang lainnya, juga berlaku untuk limbah botol kokas. , kertas bekas, sisa kapas, sepotong wol, potongan kertas bekas, tepi kertas, kapas, dll. Dan juga cocok untuk keperluan pertanian, mengemas pakan untuk penyimpanan. Tentu saja, pengguna dapat memilih model yang lebih baik sesuai dengan permintaan sebenarnya.

Fitur utama baler hidrolik vertikal

- Pemadatan hidrolik, pemuatan manual, dan pengoperasian tombol manual;

- Menjaga sepenuhnya karakteristik fisik material;

- Rasio pemadatan bahan limbah bisa mencapai 5:1;

- Dua bal untuk pengoperasian yang mudah;

- Duri anti-pantulan, pertahankan efek kompresi;

- Pelat penekan secara otomatis kembali ke posisinya.

Parameter mesin baling vertikal

| Model | SL30T | SL40T | SL60T | SL80T | SL120T |

| Tekanan hidrolik (T) | 30 | 30 | 60 | 80 | 120 |

| Ukuran tubuh (P*L) | 800*400mm | 900*600mm | 900*600mm | 1100*800mm | 3800*1200mm |

| Kapasitas penanganan (h) | 0,8-1T | 1-1.2T | 1,5-2T | 2-3T | 4-5T |

| Berat total (T) | 0.8 | 1.3 | 1.5 | 2 | 3.2 |

Mesin baler tekstil vertikal dapat dibagi menjadi tipe silinder tunggal dan tipe silinder ganda. Tekanan hidrolik umum mencapai 30 hingga 120 ton. Model mesin diberi nama berdasarkan tekanan hidrolik. Kecepatan baling adalah 6-8 bal/jam dan ketinggian setiap bale dapat disesuaikan. Tegangan dan frekuensi standar adalah 380V/50HZ dan dapat disesuaikan. Pengguna dapat memilih model mesin yang sesuai berdasarkan bahan dan jumlah pemrosesan yang berbeda.

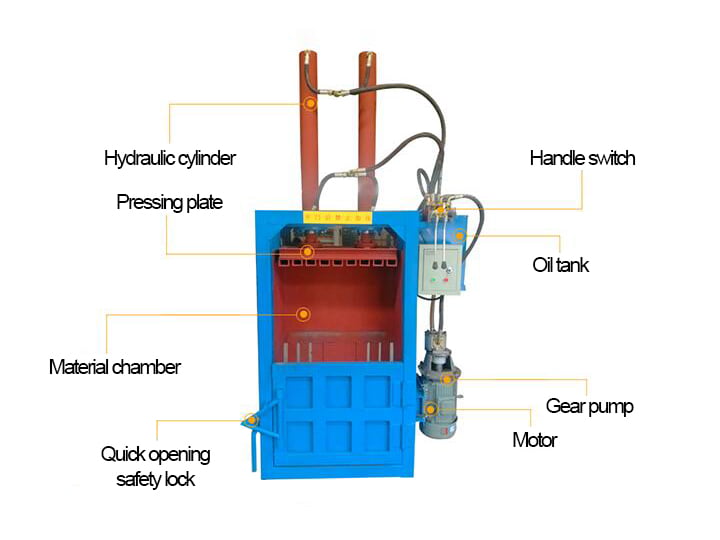

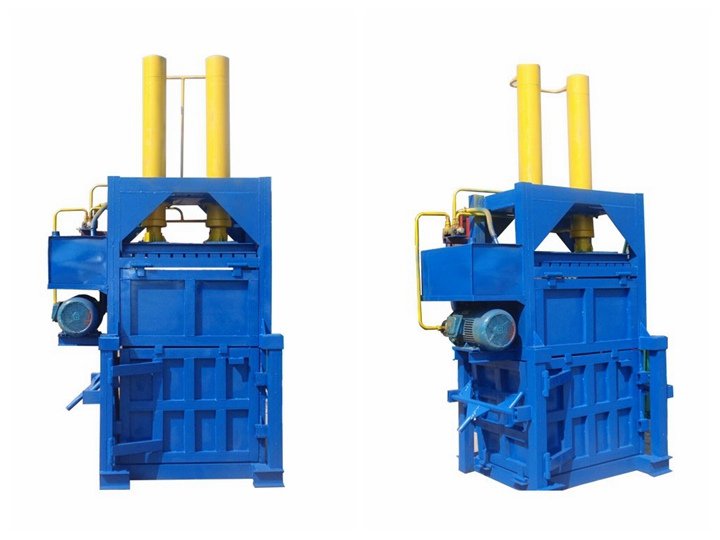

Tampilan baler hidrolik vertikal

Pertanyaan Umum

Apa saja yang harus saya perhatikan saat menggunakan mesin baling?

Air harus dihindari sebisa mungkin selama pengoperasian mesin. Hal ini karena, pertama, air menimbulkan korosi pada logam dalam sistem hidrolik baler, memperpendek masa pakai komponen, dan partikel korosi jatuh ke dalam sistem, menyebabkan keausan.

Kedua, oli hidrolik akan rusak, terutama dengan adanya air, oksigen, dan lain-lain, sehingga membentuk polimer kental, yang umumnya dikenal sebagai lumpur oli. Ketika suhu melebihi 65 derajat, laju oksidasi semakin cepat. Dan efek oksidasi berlipat ganda untuk setiap penambahan 10 derajat.

Mengapa harus memilih produsen baler yang berkualitas baik?

Memilih untuk membeli peralatan mesin baling berkualitas baik tidak hanya dapat menenangkan pikiran Anda tetapi juga menghemat uang. Biaya perawatannya rendah dan kualitas purna jual peralatan mesin baling yang lebih baik sesegera mungkin, dan Anda dapat merasa nyaman menghasilkan uang. Namun biaya pemasangan mesin baling berkualitas buruk sangat rendah, dan kualitas alam tidak dapat dijamin.

Shuliy Machinery adalah produsen mesin baler vertikal profesional selama lebih dari sepuluh tahun, mengintegrasikan pengembangan, desain, manufaktur, dan penjualan. Kami mengamati proses produksi yang ketat dan memiliki sistem kontrol kualitas yang canggih. Perusahaan kami menawarkan mesin baling berkualitas tinggi dengan sertifikasi profesional, dan layanan purna jual menyeluruh pada saat yang bersamaan. Produk kami dijual di seluruh negeri dan diekspor ke Amerika Serikat, Jepang, Spanyol, India, india, Mayasipan, Filipina, Afrika Selatan, dan banyak negara lainnya.

Apa saja yang harus diperhatikan saat melepas silinder hidrolik?

Pertama, lakukan pelepasan silinder hidrolik baler di lingkungan yang bersih untuk mencegah pencemaran debu, kotoran, dan kotoran lainnya di sekitarnya. Lindungi bagian yang dibongkar dari debu. Misalnya, tutupi bagian yang dibongkar dengan kain plastik, kain katun, dan kain industri lainnya tidak boleh ditutup.

Kedua, kosongkan kedua ruang silinder oli sebelum membongkar silinder.

Terakhir, pembongkaran harus dilakukan secara berurutan. Karena berbagai bentuk silinder hidrolik tidak sama, maka urutan pembongkarannya juga sedikit berbeda. Kepala silinder biasanya dilepas terlebih dahulu, lalu piston dan batang piston akhirnya dilepas.