婴儿尿布回收机是一条完整的生产线,设计用于高效回收使用过的婴儿尿布,通过切割、松散、筛选和除尘,有效分离绒浆、SAP、不织布和PE膜,实现材料再利用。

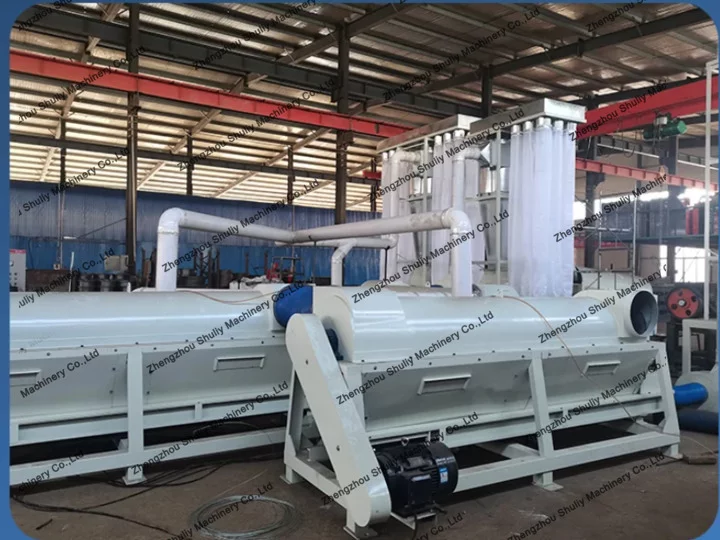

该生产线由纤维切割机、松散机、SAP筛选机、单旋风除尘器和双旋风除尘器组成。这些设备无缝配合,确保清洁分离,损失最小。

具有300–400千克/小时的处理能力,系统结构紧凑,性能稳定,非常适合中小型回收厂。婴儿尿布回收机具有高度自动化,维护简便,并可根据客户需求定制布局和配置。

哪些材料适合婴儿尿布回收机?

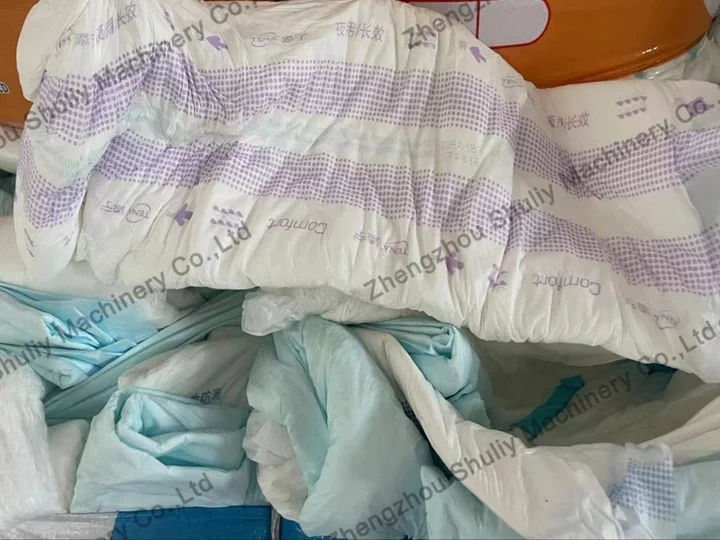

- 接近过期的成品尿布/卫生巾 – 该机器能高效处理接近保质期的产品,分离出绒浆、SAP、不织布和PE膜等可二次利用的材料。

- 生产线上的不合格或不符合标准的产品 – 任何未通过质量检验的尿布或卫生巾都可以直接回收,减少材料浪费,降低生产成本。

- 生产过程中产生的剩余修剪料和边角料 – 机器能处理生产剩余材料,帮助制造商回收宝贵的原料,提高整体材料利用率。

卫生巾回收机是如何工作的?

- 物料喂入:废弃尿布、卫生巾或有缺陷的产品倒入破碎料斗。

- 粉碎与分离:在破碎室内,机器快速将外层纸张与内部填充材料(包括SAP颗粒和吸收棉纤维)分离。

- 顺序排放:专用分离装置依次排出材料,确保分离干净高效。

- 材料再利用:分离的纸张可以回收用于造纸,而SAP和绒浆可以在各种应用中重复利用。

婴儿尿布回收机的优势

- 运行稳定:运行平稳,振动小,确保可靠的长期使用。

- 高产能:能够高效处理大量尿布。

- 低噪音: 运行安静,营造更好的工作环境。

- 高效分离:有效分离纸层与吸收短绒和SAP颗粒。

- 节能:耗能低于类似设备,降低运营成本。

回收尿布材料的应用

- 回收的SAP:用于宠物垫、育苗基质、吸收性产品和保湿材料,充分发挥其强吸收和保水性能。

- 回收绒浆:应用于塑料改性、隔音材料和家用纸生产,具有广泛的再利用潜力。

- 其他回收组件:可作为燃料用于加热或发电,实现低值材料的能源利用。

婴儿尿布回收机线参数

纤维切割机

| 参数 | 规格 |

|---|---|

| 机器名称 | 纤维切割机 |

| 电机功率 | 5.5千瓦 1.5千瓦 |

| 尺寸(长×宽×高) | 3200 × 1000 × 1100毫米 |

| 设计容量 | 300–400千克/小时 |

| 切割速度 | 每分钟432刀 |

| 切割尺寸 | 2.5–8厘米 |

| 旋转刀片 | 4个超硬刀片 |

| 固定刀片 | 2个超硬刀片 |

| 进料输送机 | 1400 × 330毫米 |

| 输出输送机 | 1400 × 330毫米 |

| 切割厚度 | 30–50毫米 |

| 电控 | 过载热保护控制箱 |

纤维除绒机

| 模型 | 分散机 1 | 分散机 2 | 分散机 3 |

|---|---|---|---|

| 电机功率 | 18.5千瓦,380V,60Hz | 15千瓦,380V,60Hz | 15千瓦,380V,60Hz |

| 机器长度 | 2500毫米 | 2500毫米 | 2500毫米 |

| 机器直径 | Φ402毫米 | Φ402毫米 | Φ402毫米 |

| 抛料板高度 | 100毫米 | 100毫米 | 100毫米 |

| 抛料板数量 | 6 | 6 | 6 |

| 底部排放 | 3000 × 520毫米,1.5千瓦 | 3000 × 520毫米,1.5千瓦 | 3000 × 520毫米,1.5千瓦 |

| 筛孔尺寸 | 10毫米 | 8毫米 | 6毫米 |

| 鼓风机 | 4.0千瓦 | 3.0千瓦 | 3.0千瓦 |

SAP筛选机

| 参数 | 规格 |

|---|---|

| 模型 | SAP筛选机 |

| 电机功率 | 11千瓦 1.5千瓦,380V,60Hz |

| 机器长度 | 3000毫米 |

| 机器宽度 | 1500毫米 |

| 筛孔尺寸 | 0.4–0.8毫米 |

旋风除尘器

| 参数 | 单旋风除尘器(2台) | 双旋风除尘器 |

|---|---|---|

| 电机功率 | 3.0 2.2千瓦,380V,60Hz | 3.0千瓦,380V,60Hz |

| 压力释放口数量 | Φ200,9个 | Φ200, 18 |

| 除尘器直径 | Φ800毫米 | Φ900毫米 |

| 鼓风机 | 3.0千瓦 | 3.0千瓦 × 2 |

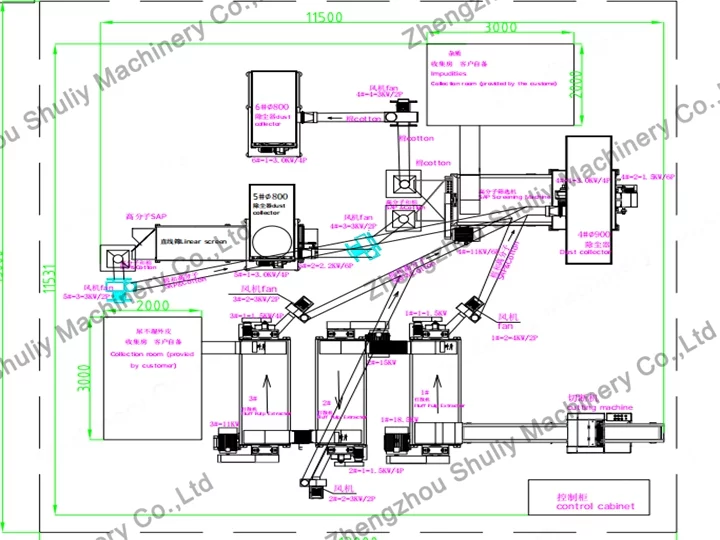

婴儿尿布回收机线布局

结论

婴儿尿布回收机是一种高效、可靠、易操作的用于回收使用过或有缺陷的尿布、卫生巾和其他吸收性产品的解决方案。

该系统不仅提高了材料利用率,降低了生产成本,还支持可持续的回收实践。

除了尿布回收线外,我公司还提供各种工业应用的其他回收设备。欢迎客户咨询价格,了解我们的全部产品。