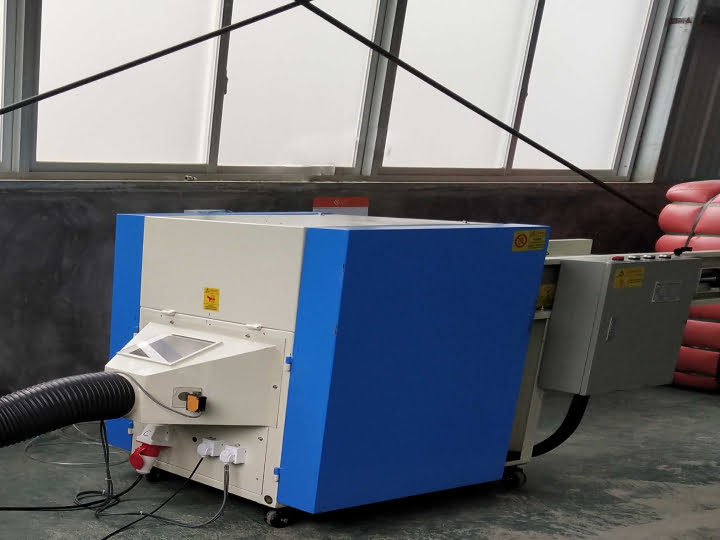

자동 면 카드기는 섬유 개방기 기계로도 알려져 있으며, PP 면, 나사 면, 인형 면, 일반 중공 면 및 다운 면과 같은 섬유를 균일하게 개방하고 느슨하게 하는 데 사용됩니다. 한 번의 개방률은 100%에 이를 수 있습니다. 섬유 카드기 기계는 장난감 공장, 소파 공장, 침대 공장, 홈 텍스타일 공장 및 의류 공장에 적용됩니다. 또한, 면 섬유 개방기는 중고 양모, 중고 양모 스웨터, 오래된 면 이불, 분쇄된 원단 및 폴리에스터 솜 찌꺼기 등을 압축하는 데에도 사용됩니다. 폴리에스터 섬유 개방기는 종종 섬유 충전기와 함께 사용되어 부드러운 섬유 제품을 만듭니다.

섬유 개방 기계 하이라이트

- 첨단 기술, 컴팩트한 구조, 강력한 파워.

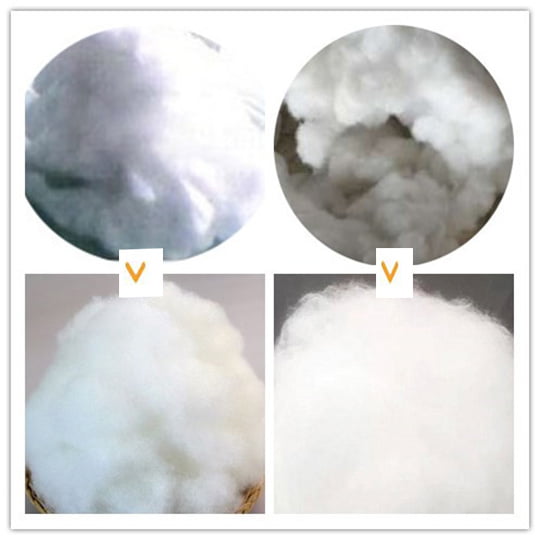

- 각종 단섬유(울, 퍼, 폴리에스터, PP면 등)를 기어 호빙 작업 시 발생하는 장력을 이용하여 빗질하고 보송보송하게 할 수 있으며, 개섬율은 99%-100%입니다.

- 전체 기계는 보호 장치로 완전히 밀폐되어 있으며 외관이 아름답습니다.

- 작동이 쉽고, 안전하고 신뢰할 수 있으며, 설치가 쉽습니다.

- 면 카딩 기계는 다른 기계와 결합하여 개방 및 충전 공정과 서로 다른 섬유 간의 혼합, 교반 및 충전을 완료할 수 있습니다.

면 소면기의 구조 및 작동 원리

1. 섬유 소면기는 큰 핀 롤과 많은 작은 핀 롤에 의해 달성되는 차동 회전에서 1400r/min의 고속으로 원면을 앞에서 뒤로 만 번 이상 풀 수 있습니다. 원재료를 손상시키지 않고 개봉 및 풀림의 목적을 달성할 수 있습니다.

2. 핀롤의 경우 무봉강관을 사용하여 홈을 가공합니다. 면방적 빗질용 특수 수입 합금 강철 랙이 감겨 있습니다. 메인 롤러에 고속 밸런싱 처리가 이루어졌습니다. 왼쪽과 오른쪽 사이의 오차는 0.1-1g에 불과하므로 기계의 보다 부드럽고 안정적인 전송을 보장할 수 있습니다. 또한 전체 면 카드기의 서비스 수명이 길어지고 유지 관리 비용이 낮아집니다.

3. 복합 산업용 벨트는 목화를 자동으로 공급하는 데 사용할 수 있으며, 이는 쉽고 안전한 작동, 더 긴 연속 작동 및 낮은 유지 관리율이라는 장점이 있습니다.

4. 목화 공급 및 배출은 전자 적외선에 의해 자동 제어되며 과부하 및 고온 보호를 위해 통합 전자 상자 제어가 가능합니다.

5. 면 섬유 오프닝 기계는 확고하고 내구성 있는 특성을 제공하기 위해 전문 판금 스탬핑을 통해 국가 표준 강판으로 만들어졌으며 일반 코팅보다 수명이 길고 페인트 제거 및 색상 변경 없이 바니시를 감전 및 스토브로 마무리됩니다.

섬유 소모기 기술 데이터

| 방법 | SL-1500 | SL-1800 | SL-2100 |

| 사양 | 1900×880×1100mm | 1900×1180×1100mm | 1900×1380×1100mm |

| 힘 | 220/380V | 380V | 380V |

| 힘 | 3.75KW | 4.75KW | 6.25KW |

| 생산하다 | 200-250KG/H | 350-400KG/H | 500-550KG/H |

| 무게 | 450KG | 600KG | 750KG |

| 개통율 | 100% | 100% | 100% |

폴리에스터 섬유 개봉기를 작동하는 방법은 무엇입니까?

1. 면 소면기의 시작 버튼을 눌러 주 전원 공급 장치를 켭니다. 반전 스위치는 컨베이어 벨트가 자동으로 앞뒤로 움직이도록 제어하는 데 사용됩니다.

2. 예를 들어 컨베이어 벨트가 벗어난 경우 왼쪽의 조정 레버를 단단히 조이고 왼쪽으로 이동할 때 오른쪽의 조정 레버를 약간 느슨하게 조여야 합니다. 오른쪽의 조정 레버를 단단히 조이고 오른쪽으로 움직일 때 왼쪽도 약간 느슨하게 조여야 합니다.

3. 롤러 기어가 손상되어 개구율에 영향을 미칠 수 있으므로 딱딱한 물건을 넣지 마십시오.

4. 작동 중인 전동 부품, 개방 기계 롤러 및 기타 부품을 만지는 것을 엄격히 금지하며 면화 공급을 위해 면 프레스 롤러에 손을 대는 것을 엄격히 금지합니다.

5. 섬유 개봉 기계의 뒷부분에 있는 개봉 및 풀린 면 섬유는 적시에 제거하여 따로 보관하거나 면 충전 기계로 운반해야 하며 섬유 개봉 기계에 쌓이는 것은 섬유를 차단하는 것을 엄격히 금지해야 합니다. 기계 롤러를 열면 모터가 타서 다른 변속기 부품이 손상됩니다.