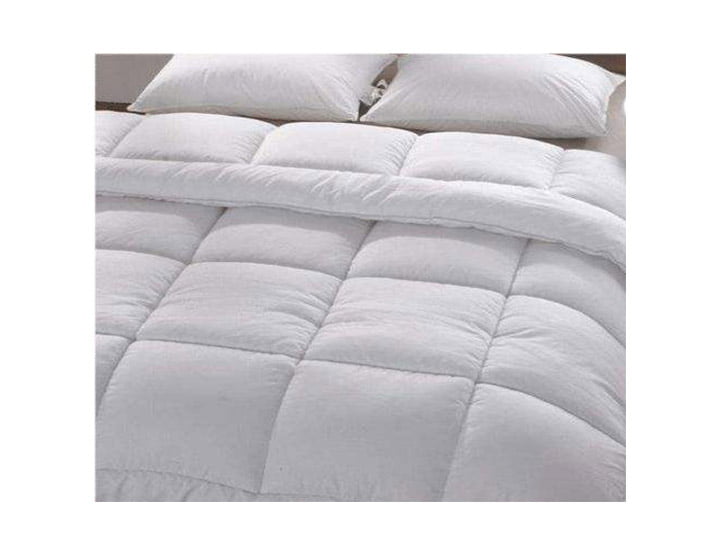

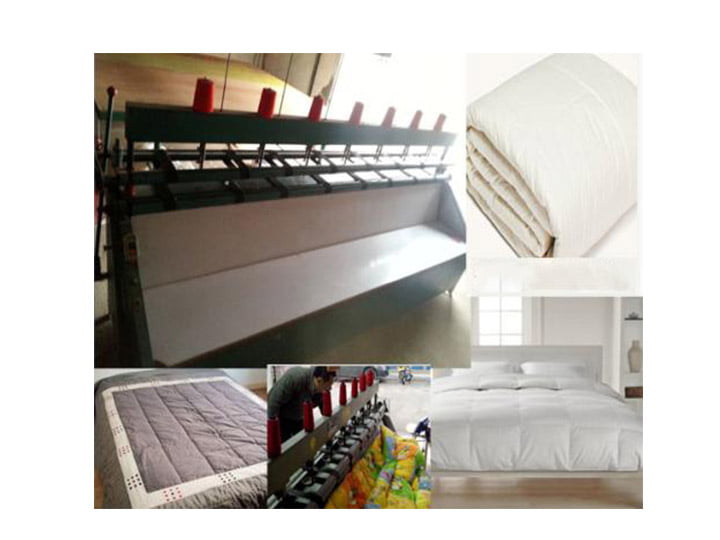

A linear quilting machine or straight line quilting machine is a kind of textile machinery used to sew linear patterns on various quilts, mattresses, bedspreads, and so on. The line on the products is straight and good-looking, without a quilted head. The needle distance is uniform and the distance is adjustable. There are many models, such as 7-needle, 9-needle, 16-needle model, etc. for options. The processing thickness is adjustable, and the length of the quilt that can be used for sewing is unlimited. One person can sew a quilt in two minutes. The multi-needle quilting machine can make about 170 quilts with no need of changing the thread. The weight of quilts can be up to 16-18kg of the super thick quilt. In addition, the straight line quilting machine can be customized according to customer needs. The linear quilting equipment is widely used, including quilts (cotton quilt, down quilt, silk floss quilt, silk quilt), greenhouse thermal insulation quilt, vehicle thermal insulation quilt, student quilt, thick curtain, quilt cover, cushion, footpad, outer packages of various materials.

Structural features of linear quilting machine

The multi-needle linear quilting machine consists of the upper needle beam, lower crochet shaft system, iron roller, deceleration half shaft, vertical shaft, and other main parts. It adopts the gantry type stitching method, which stitches multiple threads at the same time and uses the super large rotary shuttle to hook the thread, resulting in a lock stitch link. The stitch is straight, flat, beautiful with no thread disconnection. The multi-needle quilting machine comprises rising (falling) supports with equal length, which moves up and down through independent operating rods. There are a group of needles on the rising (falling) supports. The needle support carrying the needle is fixed on the rising (falling) support through a guide hole. Each support rod is provided with a presser foot and elastically supported by a spring.

Multi-needle quilting machine highlights

- High efficiency,can finish one quilt within 2 minutes.

- 6 models for option: 7-needle, 9-needle, 10-needle, 11-needle, 12-needle, 16-needle. Accurate needle feeding and uniform needle spacing. The bottom thread design realizes good flatness and accurate stitching. Double line flat seam replaces the traditional single line chain structure.

- Continuous stitching, straight line and equal stitch distance, with no limit on the length of the quilt.

- The sewn single lines are beautiful, firm and elastic.

- Scientific threading, moderate tightness and beautiful sewing.

- A winding device of the linear quilting machine facilitates the winding of rotary shuttle. The large rotary shuttle is designed to wind as long as 600 meters at a time.

- Simple structure,safety and easy to operate.

- Low investment and quick return.

- Wide application: suitable for various textilte materials, including quilts, greenhouse thermal insulation quilt, vehicle thermal insulation quilt, curtain, quilt cover, cushion, packaging.

Technical parameters of straignt line quilting machine

| Model | Needle number | Dimension | Capacity | Powder | Rotary speed | Needle model | Needle distance |

| SL-07 | 7 | 2.8*0.8*1.5m | 1 quilt/2minute | 1.5kw | 60r/minute | 25*450 | 25-50mm |

| SL-09 | 9 | 2.8*0.8*1.5m | 1 quilt/2minute | 1.5kw | 60r/minute | 25*450 | 25-50mm |

| SL-10 | 10 | 2.8*0.8*1.5m | 1 quilt/2minute | 1.5kw | 60r/minute | 25*450 | 25-50mm |

| SL-11 | 11 | 2.8*0.8*1.5m | 1 quilt/2minute | 1.5kw | 60r/minute | 25*450 | 25-50mm |

| SL-12 | 12 | 2.8*0.8*1.5m | 1 quilt/2minute | 1.5kw | 60r/minute | 25*450 | 25-50mm |

| SL-16 | 16 | 2.8*0.8*1.5m | 1 quilt/2minute | 1.5kw | 60r/minute | 25*450 | 25-50mm |