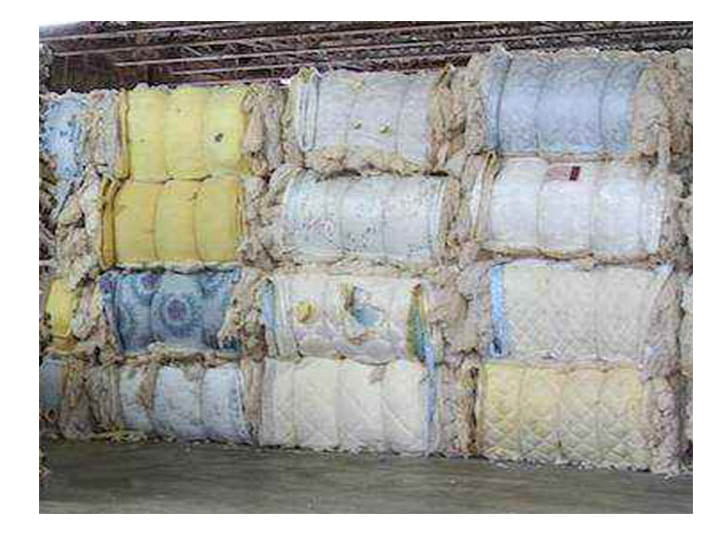

A vertical hydraulic baler is mainly used for the pressing and recovery of compressed textiles, cotton, fabric, fiber, cardboard, waste film, waste paper, foam plastics, beverage cans, industrial scraps, and other waste materials. For fiber recycling, a fiber baler machine is often applied to bale various fibers for convenient storage and transport in the waste fiber recycling line. The textile baling machine reduces waste storage space, saves up to 80% stacking space, reduces transportation costs, and is conducive to environmental protection and waste recovery.

Uses of vertical hydraulic baling machine

This series of hydraulic baling machines can be used for packing all kinds of waste products for recycling. In textile industries, the textile baling machine can bale various kinds of waste fabric, cotton, yarn, wool, clothes, coconut fiber, flax fiber, leather, chemical fibers, etc. In other recycling industries, it is also applicable to waste coke bottles, waste paper, waste cotton, woolen sliver, scrap paper strip, paper edge, cotton, etc. And it is also suitable for farm use, packing feed for storage. Of course, users can choose the better model according to the actual demand.

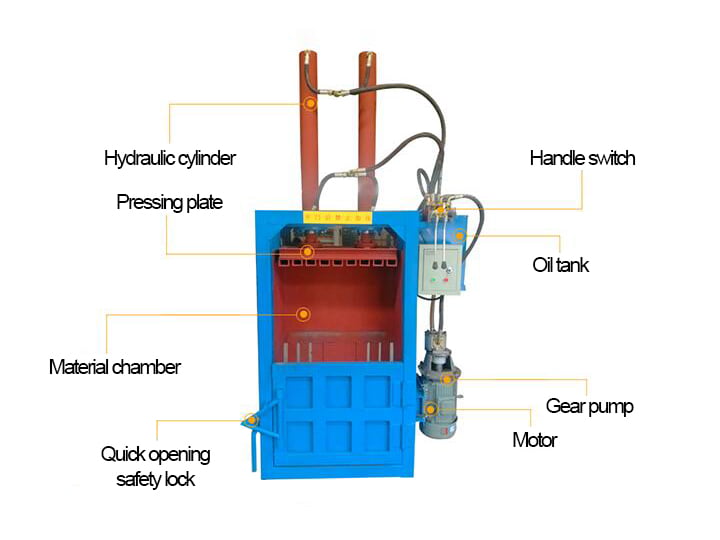

Main features of vertical hydraulic baler

- Hydraulic compaction, manual loading, and manual button operation;

- Completely maintain the physical characteristics of the material;

- The waste material compaction ratio can reach 5:1;

- Two bales for easy operation;

- Anti-rebound barbs, keep the compression effect;

- The pressing plate automatically returns to position.

Vertical baling machine parameter

| Model | SL30T | SL40T | SL60T | SL80T | SL120T |

| Hydraulic pressure(T) | 30 | 30 | 60 | 80 | 120 |

| Body size (L*W) | 800*400mm | 900*600mm | 900*600mm | 1100*800mm | 3800*1200mm |

| Handling capacity (h) | 0.8-1T | 1-1.2T | 1.5-2T | 2-3T | 4-5T |

| Total weight (T) | 0.8 | 1.3 | 1.5 | 2 | 3.2 |

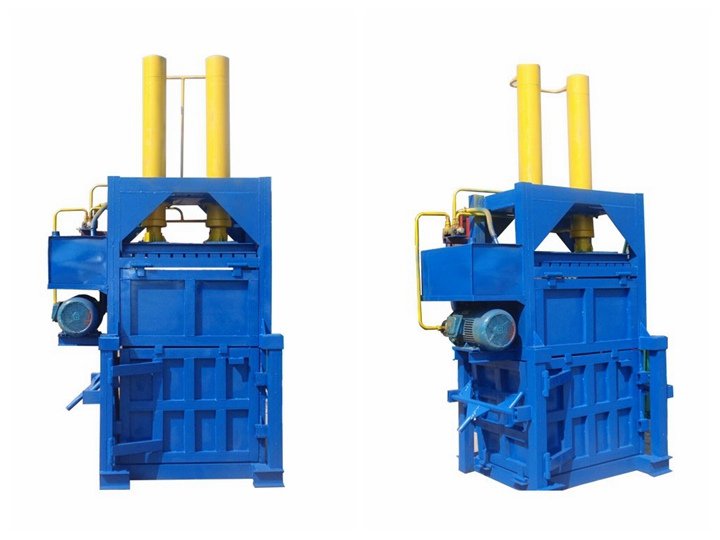

The vertical textile baler machine can be divided into the single-cylinder type and double-cylinder type. The general hydraulic pressure reaches from 30 to 120 tons. The machine model is named based on the hydraulic pressure. The baling speed is 6-8 bales/h and the height of each bale is adjustable. The standard voltage and frequency are 380V/50HZ and they can be customized. Users can choose a suitable machine model based on different materials and processing quantities.

Display of vertical hydraulic baler

FAQ

What should I pay attention to when using a baling machine?

Water should be avoided as much as possible during machine operation. This is because, in the first place, water corrodes the metal in the hydraulic system of the baler, shortening the service life of the components, and corroding particles fall into the system, causing wear and tear.

Secondly, hydraulic oil deteriorates, especially in the presence of water, oxygen, etc, forming a viscous polymer, generally known as oil sludge. When the temperature exceeds 65 degrees, the oxidation rate is accelerating. And the oxidation effect multiplies for every 10 degrees added.

Why should choose a good quality baler manufacturer?

Choosing to buy good quality baling machine equipment can not only set your mind rest but also save money. The maintenance cost is low and the better quality of the baling machine equipment after-sales as soon as possible, and you can feel at ease making money. But the fitting cost of the poor quality baling machine is very low, and the quality of nature can not be guaranteed.

Shuliy Machinery is a professional vertical baler machine manufacturer for over ten years, integrating development, design, manufacturing, and sales. We observe the strict production process and have advanced quality control systems. Our company offers high-quality baling machines with professional certifications, and all-around after-sales service at the same time. Our products are sold all over the country and exported to the United States, Japan, Spain, India, Indonesia, Mayasipan, the Philippines, South Africa, and many other countries.

What should be paid attention to when removing the hydraulic cylinder?

Firstly, carry out the removal of the hydraulic cylinder of the baler in a clean environment to prevent pollution by surrounding dust, impurities, and other dirt. Protect the disassembled parts from dust. For example, cover the disassembled parts with plastic cloth, cotton cloth, and other industrial cloth shall not be covered.

Secondly, discharge the two chambers of the oil cylinder before disassembling the cylinder.

Lastly, disassembling should be in sequence. Because various hydraulic cylinder forms are not the same, the disassembly sequence is also slightly different. The cylinder head is usually removed first, and the piston and piston rod are finally removed.